When most people think of surveying, instruments such as total stations and GNSS receivers usually pop into mind. However, one of the quickest and most accurate types of instrument that some may not know about are 3D laser scanners. With 3D laser scanners, certain surveying jobs can be finished far quicker and with better efficiency.

What Are 3D Laser Scanners Used For?

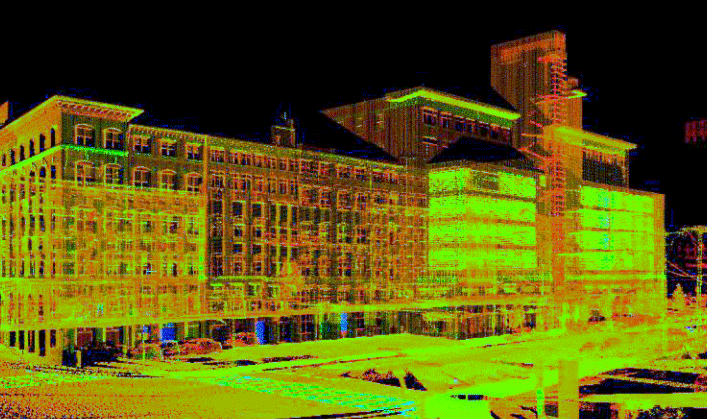

There are several key uses that a 3D laser scanner can be used for. The main uses of a laser scanner involve taking the dimensions of a building, layout of a piece of land, etc. This is extremely useful to help planning and design phases of the construction or renovation of a building. Additional applications include tunnel surveying, damage documentation, and any other alterations that have been made to a structure.

With its ability to scan a building/structure, the overall cost and time spent at a jobsite can be greatly reduced. Having a 3D scanner reduces the amount of people that need to be sent out for the job; they are also very accurate which will lessen the amount of times that an area needs to be reshot. With how many data points that get captured, the laser scanner can create a ‘digital twin’ of the area being scanned. The benefits of having a digital twin is that it shows a very detailed copy of the scanned area, helping the surveyor find exact measurements and find any details that they may not have seen.

What Are The Main Benefits of Using a 3D Laser Scanner

Now that we’ve gone over what a 3D laser actually does, we will go into what are all the benefits that come with using it. Some of the most beneficial aspects that come with using a 3d scanner include a large decrease in the time spent on a job, lower the personal and cost involved, and lessen the potential risk involved.

A laser scanner eliminates the need for a whole array of accompanying equipment, meaning a smaller crew is required as there is much less equipment to man. The process in which it collects its data is also unreliant on its users calculations, meaning that there is a far less chance of being an error. Less errors also means that the surveyors will need to visit the jobsite less times, saving both valuable time and money. You also don’t have to sacrifice when it comes to distance as many scanners can cover a large area. An additional benefit is in the event that a surveyor has to take a scan of a potentially dangerous or difficult to reach area, the 3D scanner will remove their risk as they don’t have to get close to get their points.

All the benefits that come with utilizing a 3D laser scanner will provide your business with a distinct edge over other companies that have yet to adapt to using 3D scanners. With the speed and accuracy that comes with using a scanner, your company will be able to complete jobs much quicker. This is mutually beneficial to both the company and the customer; leading to a quicker turnaround on jobs and happier customers.

What are the different types of 3D scanners available

While we have established the many benefits that come with using a 3D laser scanner, we have yet to go over the different variations of scanners. The main differences between the different types revolve around the distance that you need from the unit. There are different methods that differentiate between how the units collect the data, these methods make some better suited for longer range readings and others more capable for shorter ranges. Some examples of the different scanning methods are laser pulse-based 3D scanners, structured Light 3D Scanners, and laser-based 3D Scanners.

The other differentiating factor is the size of the 3D scanner. While most 3D scanners are meant to be attached to devices such as a tripod and as such, are larger in size. However, there are exceptions to this such as the Stonex F6 which is a handheld scanner. Smaller scanners like this tend to have a short scanning range but they are easy to operate and to scan specific items. Should you have a job in an easy to access area in which all the items you’ll be scanning are in close proximity, then a handheld scanner would be perfect for you. However, should you need to scan a large area or an item that’s at a distance, opting for a larger 3D scanner would be the best option.

To check out all of the 3D Laser Scanners that SiteSurv offers, click on the links below.

https://www.sitesurvusa.com/products/instruments/3d-laser-scanners

https://www.sitesurvusa.com/products/instruments/3d-laser-scanners/stonex-f6-laser-scanner

https://www.sitesurvusa.com/products/instruments/3d-laser-scanners/stonex-x150-laser-scanner

https://www.sitesurvusa.com/products/instruments/3d-laser-scanners/stonex-x300-laser-scanner