Written By Kai Escobar

We’ve all seen or heard of people buying metal detectors to scan their backyard or the beach looking for some sort of precious metals hidden underground. While this may not seem very relevant when it comes to surveying, the use of magnetic locators draws some parallels as they are similar devices. How are magnetic locators used in surveying though? Magnetic locators are a key part of identifying potential metal hazards or obstructions that are underground at a jobsite. We’ll go over how magnetic locators work, how to properly use them, and key things to look for when picking a locator to buy.

How do magnetic locators work?

While you may think that a regular metal detector would be suitable for surveying, you would be mistaken. The reason for this is that conventional metal detectors struggle when it comes to finding ferrous metals, which are a commonplace on a jobsite. The difference between ferrous metals and non-ferrous metals is that ferrous metals have iron in them. Fortunately, magnetic locators are the perfect device to detect ferrous metals.

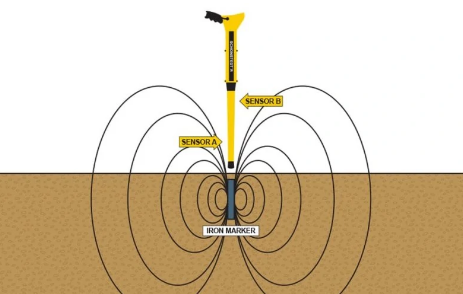

Another difference between a magnetic locator and a metal detector is that when scanning, it isn’t searching for the metal itself. The locator’s sensors are looking for the distinct disorientation that metal would cause in the magnetic field.

An important factor when searching for metals is the length of the locator that you are using. Since the sensors are on the sides of the locators, the length of the locator will help determine how sensitive the locator is. This greatly affects the device’s ability to detect metals that are deeper underground, so if you need to find utilities that may be deep you need to make sure that you use a longer magnetic locator.

Another key differential between locators are their sensitivity settings. The amount of different sensitivities that a locator offers differs between each unit. This becomes important when you want to specifically search for items of a certain size and/or depth without being interfered with by objects of a different size or depth than what you are searching for.

How to use and select a magnetic locator

So now you know the mechanics of how a magnetic locator works, but what exactly are magnetic locators used to find? There is a wide array of items but some of the most important and common ones that you should know are water/gas lines made of iron, manhole covers, PK nails, pipes, wires, and any buried metal items. Whether they are under the ground or under water, a magnetic locator is capable of finding these items and more. However, certain locators do not have a response to certain materials; for example the Schonstedt SPOT Magnetic Locator doesn’t pick up aluminum, brass, or copper.

When it comes to selecting which brands to buy, there are a couple of trustworthy brands that you can rely on to get you good results. Some brands that we highly recommend are Schonstedt, SmartTrak, and Dunham and Morrow. With Schonstedt you have instruments such as the SPOT locator which has many of the features of the popular GA-52Cx model but with a more durable and lightweight design. SmartTrack, which is a David White brand, has pinpoint accuracy and also offers a visual display for the operator. Dunham and Morrow DML2000-XRM offers many different options to adjust both the sensitivity and the volume, with there being six different levels of sensitivity and four for the volume.

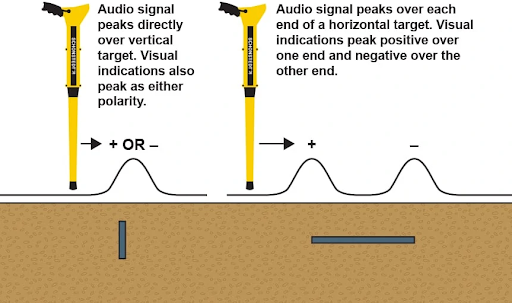

When you are using a locator and you first hear the locator sound go up indicating that you have found something underground. However, the next step is to find out exactly what it is by finding out what its shape is. The first thing you’ll need to do is to figure out if the buried object is turned vertically or horizontally. To do this move the locator around the area where the audio spiked, if it only spikes over one spot and not any others then it is turned vertically. Another important thing to determine is its depth, this is done by paying attention to the sensitivity that your locator is set on. You can also switch between the different settings to see if the object goes any deeper or closer to the surface. To determine exactly how deep an item is comes with learning your device over time to accurately assess how deep each sensitivity is; that is unless your locator has a display which can show you.

With the importance of locators to learning about the jobsite and all of its potential hazards and obstacles, learning how to choose and use a magnetic locator is essential. As always, we hope that this article has been able to help you increase your efficiency out on the field.

To see all of the magnetic locators that SiteSurv has to offer, click on the links below!